|

Cryostat Applications

The unique properties of aerogels previously described make them suitable

for a variety of innovative applications. Aerogel beads have been made as a cryogenic thermal insulating system at the Cryogenics

Test Laboratory at the NASA Kennedy Space Center. In comparison to conventional insulating products like pearlite powder and

multilayer insulation (MLI), aerogel beads are “significantly better” (Breon, 2002). The main advantages include:

free flowing, minimal dusting, non-settling, and that it can be formed using binders. These properties, combined with the

very good insulating capability of aerogel, make it the most utilized cavity packing material for cryostat applications.

Glass Pane Window Replacement

|

| Aerogel windows for better insulation |

“In the ‘Technology to Watch’ section of Fortune Magazine,

the use of aerogels was cited for more than 800 different product applications ranging from satellites to surfboards”

(Walls, 1998). Currently aerogels that are produced in gravity have a slight blue haze to them. This blue color arises from

the presence of large pores formed during the gellation process. NASA is currently working on a project trying to prove that

aerogels produced in zero gravity would be completely transparent (Steiner, 2002). This useful property makes aerogels ideal

for replacing glass window panes in homes as shown in the figure to the right. Not only are they as transparent as standard

soda-lime glass, they insulate 10-20 times better. This makes them suitable for future applications such as energy saving

skylights, oven door panels, space-saving refrigerators, and lightweight picnic coolers (Walls, 1998).

|

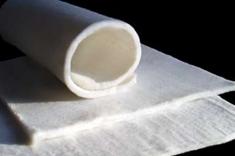

| Aspen Aerogel's flexible aerogel blankets |

Aspen Aerogels,

founded in 2001, is now making flexible blankets that are used for high temperature thermal insulation, sound absorption,

and fire suppression across a range of military and aerospace applications (Banke, 2004). Most recently the insulation in

some lightweight winter coats has been replaced with aerogels.

|

| Aerogel as an oil pipe insulator |

Aerogel is also being implemented as an

insulator in offshore oil pipes. Due to its higher thermal efficiency less material has to be used and the pipe’s diameter

can be significantly decreased as shown in the figure to the right. This saves space and considerably reduces the installation

costs (Aerogel Morphology, 2006).

Space Dust Collector

The most prominent user

of aerogel is NASA. NASA first used aerogel in 1999 to collect space dust (Brownlee, 2003). Due to the large velocity that particles in space usually have, collecting

them is an engineering challenge. Despite the relatively small mass of these particles their momentum is so high that collecting

these particles using a rigid object is almost impossible. The particles were first analyzed by looking at residues they left

in metal and also impact debris. If a suitable highly porous material could be obtained, the particles could be brought to

a rest in the material. In order to leave the particles and the space craft undamaged, the particle had to be slowed down

carefully.

This was achieved by using a thick layer of aerogel. When the particle hits the aerogel, it penetrates the aerogel

and slows down gradually in the process. If the layer of aerogel is thick enough, the particle is brought to a halt before

it reaches any rigid materials.

|

| Particles penetrating the aerogel and leaving conical tracks |

These

hypervelocity particles bury themselves in the aerogel and leave narrow cone-shaped tracks as shown in

the figure to the right. The particles can then be retrieved by a number of methods including extraction by a needle, microtoming,

and focused ion beam etching. “Recovered samples are then treated by sequential analysis techniques that have been developed

for the analysis for small meteoritic samples and interplanetary dust particles” (Todd, 2007).

|

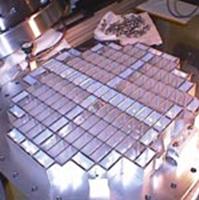

| Aerogel grid used to catch comet dust |

During the NASA Stardust mission, aerogel was

mounted on both sides of a grid of 160 sections on a deployable arm as shown in the figure to the left. During takeoff, landing,

and in flight, the spacecraft collected dust on only one side of the aerogel grid. When it flew past the comet in 2004, the

unused side of the grid was flipped over and caught up to 2800 particles that were 15 microns or larger traveling at 6.1 km/s

(Tuzzolino, 2006). “The captured particles in the laboratory studies all retain unaltered domains, which yield their

original structure and composition” (Burchell, 2006).

|